Kubbada Qaadista Yaryar

XAALADAHA DHASHAY

| Qaadista No. | aqoonsi | OD | W | Qiimaynta Xamuulka (KN) | Xawaaraha ugu badan | |

| d | D | B | Firfircoon | Joogta ah | Saliid | |

| mm | mm | mm | Cr | Kor | r/min | |

| 603 | 3.000 | 10.000 | 4.000 | 0.5530 | 0.2030 | 49500 |

| 604 | 4.000 | 12.000 | 4.000 | 1.1700 | 0.4360 | 40500 |

| 605 | 5.000 | 14.000 | 5.000 | 1.1970 | 0.4540 | 40500 |

| 606 | 6.000 | 17.000 | 6.000 | 2.0340 | 0.7560 | 37800 |

| 607 | 7.000 | 19.000 | 6.000 | 2.3580 | 0.9540 | 36000 |

| 608 | 8.000 | 22.000 | 7.000 | 2.9700 | 1.2240 | 34200 |

| 609 | 9.000 | 24.000 | 7.000 | 3.0150 | 1.2690 | 32400 |

| 623 | 3.000 | 10.000 | 4.000 | 1.1700 | 0.4360 | 45000 |

| 624 | 4.000 | 13.000 | 5.000 | 1.5660 | 0.6030 | 38700 |

| 625 | 5.000 | 16.000 | 5.000 | 1.5570 | 0.6030 | 38700 |

| 626 | 6.000 | 19.000 | 6.000 | 2.3580 | 0.9540 | 34200 |

| 627 | 7.000 | 22.000 | 7.000 | 2.9700 | 1.2240 | 32400 |

| 628 | 8.000 | 24.000 | 8.000 | 3.0150 | 1.2690 | 30600 |

| 629 | 9.000 | 26.000 | 8.000 | 4.0950 | 1.7730 | 28800 |

| 633 | 3.000 | 7.000 | 2.000 | 0.2830 | 0.1030 | 61200 |

| 634 | 4.000 | 16.000 | 5.000 | 0.5760 | 0.2030 | 59400 |

| 635 | 5.000 | 19.000 | 6.000 | 2.3580 | 0.9540 | 34200 |

| 636 | 6.000 | 22.000 | 7.000 | 2.9700 | 1.2240 | 30600 |

| 637 | 7.000 | 26.000 | 9.000 | 3.6000 | 1.4220 | 27000 |

| 638 | 8.000 | 28.000 | 9.000 | 0.4095 | 1.7730 | 25200 |

| 639 | 9.000 | 30.000 | 10.000 | 0.4590 | 2.1510 | 23400 |

| 684 | 4.000 | 10.000 | 3.000 | 0.5850 | 0.2120 | 49500 |

| 685 | 5.000 | 11.000 | 3.000 | 0.6430 | 0.2550 | 46800 |

| 686 | 6.000 | 13.000 | 3.500 | 0.9720 | 0.3960 | 43200 |

| 687 | 7.000 | 14.000 | 3.500 | 1.0530 | 0.4590 | 40500 |

| 688 | 8.000 | 16.000 | 4.000 | 1.1250 | 0.5310 | 38700 |

| 689 | 9.000 | 17.000 | 4.000 | 1.5570 | 0.7290 | 36900 |

| 694 | 4.000 | 12.000 | 4.000 | 0.8730 | 0.3240 | 42300 |

| 695 | 5.000 | 13.000 | 4.000 | 0.9720 | 0.3870 | 45000 |

| 696 | 6.000 | 15.000 | 5.000 | 1.5660 | 0.6030 | 42300 |

| 697 | 7.000 | 17.000 | 5.000 | 1.4490 | 0.6430 | 37800 |

| 698 | 8.000 | 19.000 | 6.000 | 2.0160 | 0.8140 | 37800 |

| 699 | 9.000 | 20.000 | 6.000 | 1.9080 | 0.8860 | 36000 |

| R2 | 3.175 | 9.525 | 3.967 | 0.5760 | 0.2020 | 52200 |

| R3 | 4.762 | 12.700 | 3.967 | 1.1790 | 0.4410 | 43200 |

| R4 | 6.350 | 15.875 | 4.978 | 1.3320 | 0.5530 | 58700 |

| R6 | 9.525 | 22.225 | 5.566 | 3.0150 | 1.2690 | 34200 |

AALADAHA XASKA LEH

Waxqabadka iyo isku halaynta biraha duubista ayaa si weyn u saameeya agabyada ay ka samaysan yihiin birta sida BXY iyo kubbadaha oo laga sameeyay tayada sare ee GCr15 vacuum-degassed steel. biraha sida shaxanka hoose:

| Xeerka caadiga ah | Qalab | Falanqaynta(%) | ||||||

| C | Si | Mn | Cr | Mo | P | S | ||

| GB/T | GCr15 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 1.40-1.65 | ≦0.08 | ≦0.025 | ≦0.025 |

| DIN | 100Cr6 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 1.40-1.65 | ≦0.030 | ≦0.025 | |

| ASTM | 52100 | 0.98-1.10 | 0.15-0.35 | 0.25-0.45 | 1.30-1.60 | ≦0.10 | ≦0.025 | ≦0.025 |

| JIS | SUJ2 | 0.98-1.10 | 0.15-0.35 | ≦0.50 | 1.30-1.60 | ≦0.025 | ≦0.025 | |

XIDHIIDHKA XAASADA

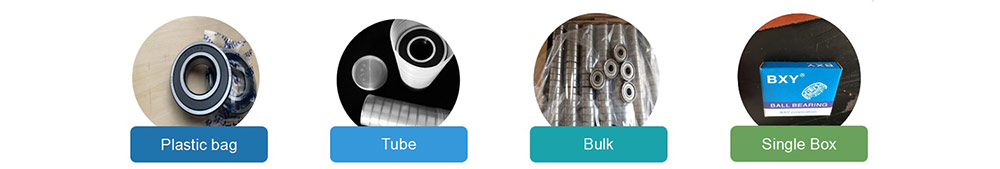

Xirmooyinkayadu sidoo kale aad bay u kala duwan yihiin, ujeedadu waa in la daboolo baahiyaha macaamiisha kala duwan. Baakadaha inta badan la isticmaalo waa sida soo socota:

1.Baakad warshadeed+kaartoon+dibadeed+pallets

2.Sanduuq+kaartoon+dibadeed+pallets

3.Baakidh Tube+sanduuqa dhexe+kaartoon+dibadeed+pallets

4.Sida shuruudahaaga

TILMAAMAHA XULKA

Xirmooyinka waxaa lagu dahaadhay walxaha lidka ku ah daxalka, ka dibna la raro oo ka baxa warshadda.Waxay socon kartaa muddo sanado ah haddii si fiican loo kaydiyo oo si fiican loo buuxiyo. Kaydinta kaydinta waa in la ogaadaa sida soo socota:

1. Ku hay meel heerkulkeedu ka hooseeyo 60%;

2. Si toos ah ha u dhigin dhulka, ugu yaraan 20 cm dhulka dushiisa ee si fiican loo dhigo;

3. U fiirso dhererka markaad isku dhejinayso, dhererka dhejiska waa inuusan dhaafin 1 mitir.